Robotic non-destructive testing

4 stars based on

66 reviews

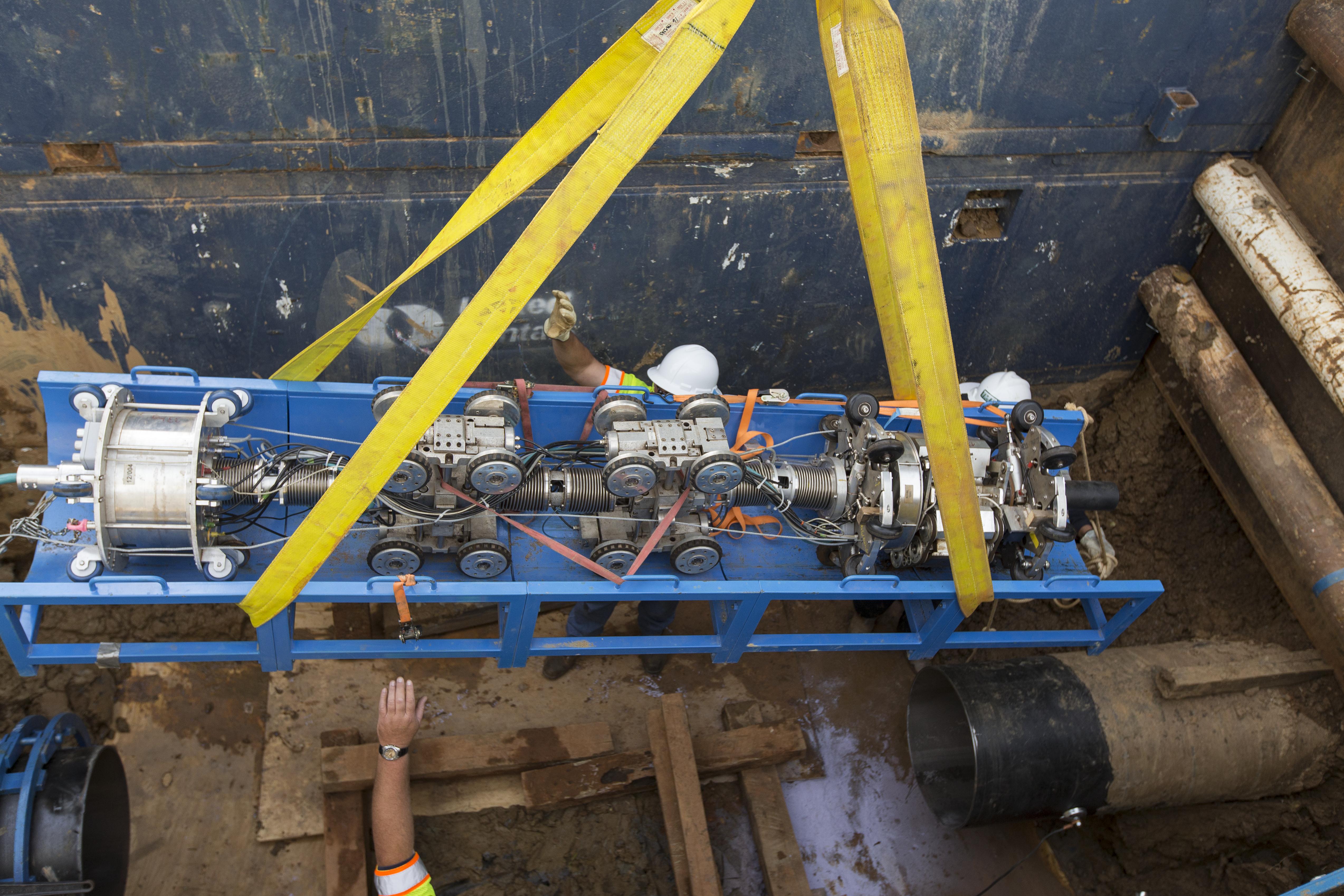

Robotic non-destructive testing NDT is a method of inspection used to assess the structural integrity of petroleum, natural gas, and water installations. Crawler-based robotic tools are commonly used for in-line inspection ILI applications in pipelines that cannot be inspected using traditional intelligent pigging tools or unpiggable pipelines. Robotic NDT tools can also be used for mandatory inspections in inhospitable areas e. These systems transmit data and commands via either a wire typically called an umbilical cable or tether or wirelessly in the case of battery-powered tetherless crawlers.

Robotic NDT tools help pipeline operators and utility companies complete required structural integrity data sets for maintenance purposes in the welding inspection gas pipes robots applications:.

Using robotics for infrastructure inspections can save the Department of Transportation millions in lane closures and heavy equipment rentals. By updating the 50year old methods currently in place for infrastructure inspections, the Department of Fransportation will get better results, allowing them to better allocate resources. Post-tension tendons that hold up large concrete structures worldwide e.

Robotic inspection devices can peer through concrete and steel and take the guesswork out of post-tension tendon inspections. Lightweight, portable without lane closures or heavy equipment can save money and prevent traffic interruptions and deadly accidents.

Replacing the manual subjective inspection with robotics within the same budget is the key to fixing and maintaining a strong infrastructure. The information provided by robotic inspections will help extend the service life of valuable infrastructure assets, keep the public safe and save billions in untimely replacements.

Tethered robotic inspection tools have an umbilical cable attached to them, which provides power and control commands to the welding inspection gas pipes robots while relaying sensor data welding inspection gas pipes robots to the technician. Tethered crawlers have the following advantages over untethered crawlers:. Untethered robotic Welding inspection gas pipes robots crawlers are powered by onboard batteries; these tools transmit sensor data wirelessly to the tool operator or store the data for downloading upon tool retrieval.

Untethered crawlers have the following advantages over tethered crawlers:. Robotic NDT tools employ suites of inspection sensors.

This section describes common sensor types; most tools combine several types of sensor depending on factors such as robot size, design, and application. Main article — Electromagnetic acoustic transducers. Electromagnetic acoustic transducers EMAT induce ultrasonic waves into uniformly-milled metal inspection objects e. Technicians can assess metal condition and detect anomalies based on the reflections of these waves — when the transducer passes over an anomaly, a new reflection appears between the initial pulse and the normal reflection.

Direct beam inspections determine metal thickness as well as detect and measure the following defects:. Angle beam inspections, where the tool induces ultrasonic waves into the metal at an angle relative to the metal surface, can be performed concurrently with direct beam inspections to confirm anomaly detections. An angle beam transducer only registers echoes from anomalies or reflectors that fall into the beam path; unlike direct beam, it does not receive reflections from the opposite wall of normal steel.

The combination of angle beam and direct beam methods may find additional anomalies and increase inspection accuracy. However, the angle beam method has a lower tolerance for surface debris than the direct beam method. Angle beam inspections discover crack-like anomalies parallel to the pipe axis welding inspection gas pipes robots metal loss defects that are too small to detect via direct beam, including the following:.

Besides its uses in unpiggable pipelines, the non-contact nature of EMAT tools makes this method ideal for dry applications where liquid couplant requirements may make traditional UT tools undesirable e. Welding inspection gas pipes robots integrity is a crucial welding inspection gas pipes robots of pipeline safety, especially girth welds or the circumferential welds that join each section of pipe together.

However, unlike the consistent molecular structure of milled steel, welds and their heat-affected zones HAZs have an anisotropic grain structure that attenuates ultrasonic signals and creates wave velocity variances that are difficult for ILI tools to analyze. One angle-beam EMAT method employs a set of nine frequency-time FT scans on each side of the girth weld, where each frequency corresponds to a different input wave angle.

The tool merges each set of FT scans into a single frequency-time matrix scan to display weld conditions, with anomalies color-coded by severity. Main article — Magnetic flux leakage. Magnetic flux leakage MFL tools use a sensor sandwiched between multiple powerful magnets to create and measure the flow of magnetic flux in the pipe wall.

Structurally-sound steel has a uniform structure that allows regular flow of the magnetic flux, while anomalies and features interrupt the flow of flux in identifiable patterns; the sensor registers these flow interruptions and records them for later analysis. The following figure illustrates the principle of a typical Welding inspection gas pipes robots inspection tool; the left side of the diagram shows how an MFL tool works in structurally sound pipe, while the right side shows how the tool detects and measures a metal loss defect.

MFL tools are used primarily to detect pitting corrosion, and some tool configurations can detect weld welding inspection gas pipes robots. One advantage of MFL tools over ultrasonic tools is the ability to maintain reasonable sensitivity through relatively thick surface coatings e.

Main article — video inspection. Robotic NDT tools employ cameras to provide technicians an optimal view of the inspection area. Some cameras provide specific views of the pipeline e. Laser profilometers project a shape onto the object surface. Technicians configure the laser both angle of incidence and distance from the object to ensure the shape is uniform on normal metal.

Photographs of these laser distortions provide visual evidence that improves the data analysis process and contributes to structural integrity efforts. Main article — Pulsed-eddy current.

Pulsed-eddy current PEC welding inspection gas pipes robots use a probe coil to send a pulsed magnetic field into a metal object. The varying magnetic field induces eddy currents on the metal surface. The tool processes the detected eddy current signal and compares it to a reference signal set before the tool run; the material properties are eliminated to give a reading for the average wall thickness within the area covered by the magnetic field.

The tool logs the signal for later analysis. PEC tools can inspect accurately with a larger gap between the transducer and the inspection object than other tools, making it ideal for inspecting metal through non-metal substances e.

United States federal law requires baseline welding inspection gas pipes robots to establish pipeline as-built statistics and subsequent periodic inspections to monitor asset deterioration. Pipeline operators also are responsible to designate high-consequence areas HCAs in all pipelines, perform regular assessments to monitor pipeline conditions, and develop preventive actions and response plans. State regulations for inspecting pipelines vary based on the level of public safety concerns.

For example, a natural gas pipeline explosion in a San Bruno residential neighborhood led the California Public Utilities Commission to require safety enhancement plans from California natural gas transmission operators.

Excavating buried pipelines to retrieve stuck tools beneath freeway crossings, river crossings or dense urban areas would impact the community infrastructure too greatly. Natural gas and oil pipeline operators therefore rely on tethered robotic ILI crawlers to inspect unpiggable pipelines. Because other ILI tools could not navigate the pipeline geometry common to each of the eleven pump stations along the pipeline, Alyeska received approval to use a tethered robotic Welding inspection gas pipes robots crawler manufactured by Diakont to complete an inspection project at Pump Station 3.

This tool allowed Alyeska to only remove a few small aboveground fittings to permit crawler entry into the piping, saving the time and expense necessary to excavate hundreds of feet of pipe some of which was also encased in concrete welding inspection gas pipes robots to inspect by hand.

Natural gas welding inspection gas pipes robots operators can use tetherless robotic ILI crawlers for smaller distribution pipelines that are not located beneath critical infrastructure elements e. From Wikipedia, the free encyclopedia. This article needs additional citations for verification. Please help welding inspection gas pipes robots this article by adding citations to reliable sources. Unsourced material may be challenged and removed. June Learn how and when to remove this template message.

Accessed 2 March California Energy Commission, Accessed 1 March A Comparison of the Magnetic Flux Leakage and Ultrasonic Methods in the detection and measurement of corrosion pitting in ferrous plate and pipe.

Pulsed Eddy Current in Corrosion Detection. Research and Special Programs Administration, Accessed 9 March Nuclear Engineering International Magazine. Accessed 10 March Accessed 15 March Hudson Valley News Network. Retrieved from " https: Robotics Nondestructive testing Technology. Articles needing additional references from June All articles needing additional references. Views Read Edit View history.

This page was last edited on 10 Marchat By using this site, you agree to the Terms of Use and Privacy Policy.