0.3 mm MK8 Nozzle – Replicator 2/2X

5 stars based on

37 reviews

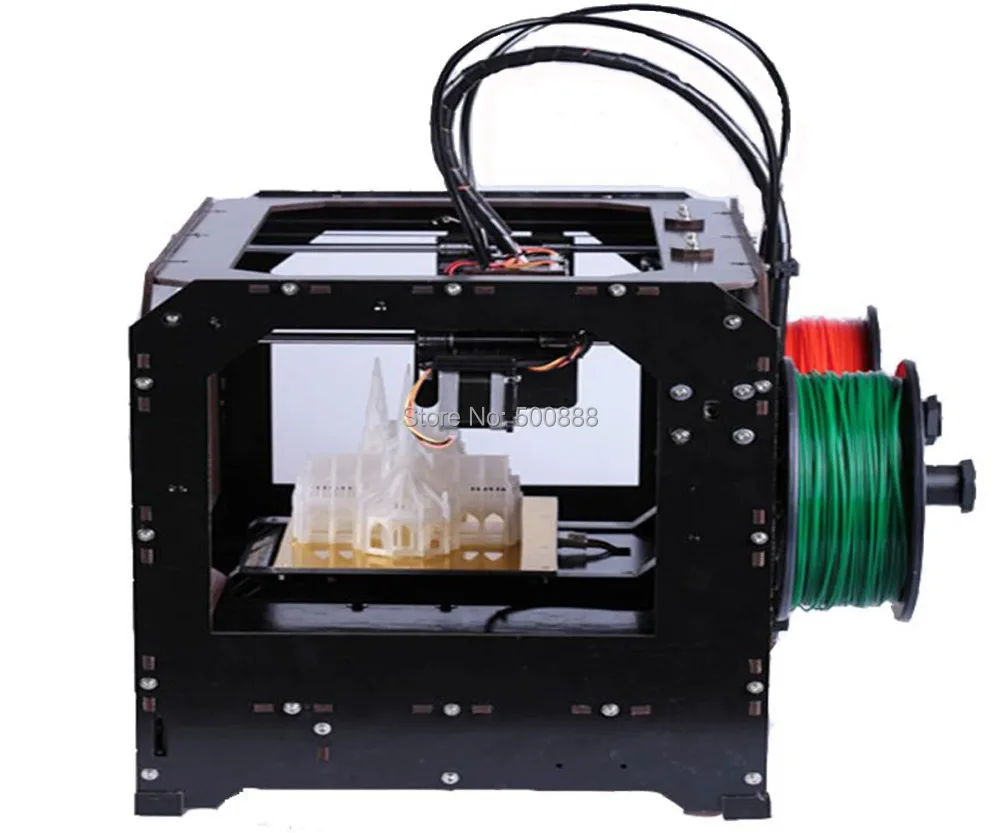

MakerBot Print is our new desktop application that allows you to prepare, manage, and monitor 3D prints. Import design files in native Ctc 3d printer makerbot replicator 2 and fine-tune their settings for optimal results when printing. Keep your projects organized by automatically arranging models across one or several build plates. Kick-off prints, control your printer, and monitor print progress remotely. Designed for the Plus Generation of Printer.

Offers limited capabilities with 5th generation printers and offline export only with previous models. Still looking for MakerBot Desktop? Download MakerBot Print 3. Before installing MakerBot Print 3. Requires firmware version 2. IT Professionals, please click here for instructions on enterprise deployment. AMD or Intel, post Users cannot import MakerBot. MakerBot Print Support Site. IT Staff, please click here to learn more. Other bug fixes and improvements.

Fixed bug that led to some Project files failing to open Fixed security vulnerabilities Other bug fixes ctc 3d printer makerbot replicator 2 improvements. Create your own Custom Print Modes, giving you quick access to your favorite combinations of print settings.

Share custom print modes with peers by exporting the print mode. Use someone else's Custom Print Mode by using the Import feature. Gain access ctc 3d printer makerbot replicator 2 advanced print settings when connected to a printer with an Experimental Extruder attached. Print settings can now be individually displayed in the Print Settings sidebar menu. This option can be enabled in the Custom Settings menu.

Current extruder temperature is now visible in the main screen of the Printer Panel OBJ files are now supported for Mac. Printers that do not utilize z-calibration have been blocked from running that procedure. Reset to factory has an added "Clear Calibration Settings" option if a Replicator Mini or Replicator 5th Generation has been set with unnecessary calibration values.

Resolved an issue where. Fixed an issue where the Orient tool was not working correctly. To completely resolve the issue, you must reset all custom print settings by right-clicking an added custom setting and selecting "Reset All to Default Value". Opening a project will prompt you to choose between the current settings and the Project settings, if they differ MinFill Print Mode is now available for Replicator 2 New custom setting: Donut-fill Happy National Donut Day!

Custom Settings UI Improvements: Custom settings that are added but not changed may change if certain other associated settings are changed e. This is intentionally done to improve print quality but will not happen if you explicitly select a Shell Print Speed after adding this custom setting Bug fixes: The slice progress bar for Replicator 2 and Replicator 2X should no longer fluctuate during the slice process.

Fixed bug where material estimates were overestimating the amount of filament necessary to print. A new Print Mode that reduces print time and saves filament by only printing the minimum amount of infill needed to support your print.

Support for SolidWorks files Windows only Other bug fixes and improvements. More intuitive default mouse controls for new users. For more information Click Here A new and improved Scale tool that lets you modify a model's ctc 3d printer makerbot replicator 2 by directly changing its overall dimensions.

Ability to reset a printer to its factory settings in the printer utilities menu. File name display field refinements. Balanced, MakerBot's standard set of print settings which balances print quality and speed Draft, which optimizes for speed Ability to start prints directly from the printer's details menu Improvements to canceling in progress slices and prints, including a new confirmation prompt when canceling a print Other bug fixes and improvements.

Import STL files as an assembly Projects: Create projects to save the designs, print settings, and build plate layout of designs as one file for easy print scheduling. Makerbot Print will automatically arrange the files on your build plate or across your whole project Cloud-Enabled Management: Remotely control multiple printers from MakerBot Print. Start, control and monitor prints with the help of camera feeds and status updates.

Preview the ctc 3d printer makerbot replicator 2 that the extruder will take to create a print. Review layers individually or watch simulated preview to: Make adjustments before printing a model View support material placement Validate small features are printable Ctc 3d printer makerbot replicator 2 Software Updates: Print settings displayed on printer may report incorrect or zero values and may not reflect the actual settings being used by the print.

It is possible to get in a state where Chamber Heater Temperature and Build Plate Temperature are selectable options for printers not equipped with a heated chamber or build plate. If enabled on these printers, these settings will be ignored.

If there are issues selecting models while using an external display, restarting the app will resolve this problem. Rendering of utilities panel when printer loses connection to the computer. Display error WebGL context loss when plugging a computer into certain external displays A windows user name containing non ASCII characters are not supported When switching between two different printers of the same model e.

We recommend you always reslice when switching between different printers. Intermittent crashes when slicing large files. Replicator 2x only supports single extrusion. I have a question about an existing order. I have a ctc 3d printer makerbot replicator 2 question about my device.

For faster service, enter your order number found in your confirmation e-mail Skip.